Many people globally think that 3D printing and additive manufacturing is the same thing. Though the two terms are about manufacturing processes that entail building objects through adding material, there is a slight difference between the two.

What is 3D printing?

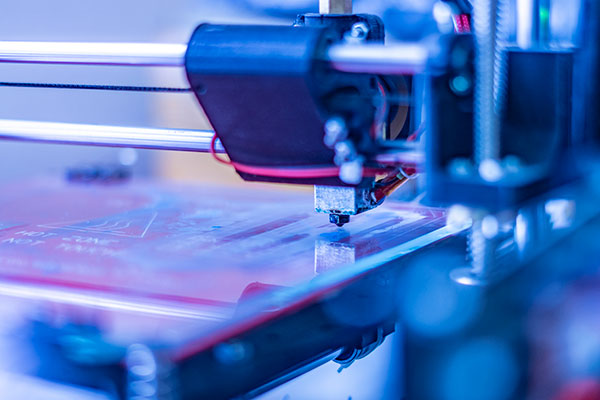

It is a manufacturing process that creates objects layer by layer. You start by laying the base layer, and then you add subsequent layers until you create a complete object. Experts use a 3D printer and CAD software to build the items. Unlike in milling, where you create objects by removing material from a workpiece, 3D printing creates objects through the deposit of material layers.

The CAD software directs the 3D printer on the amount of deposit material and the place to deposit the material. Most 3D printers employ polymer as the printing material.

What is additive manufacturing?

Additive manufacturing involves creating objects through adding material. 3D printing is a type and form of additive manufacturing. When you create an object through adding material rather than removing it, the process is additive manufacturing. Just like 3D printing, it uses a machine and CAD software. The CAD software gives the machinery instructions to build an object by adding material.

The distinction between additive manufacturing and 3D printing is that additive manufacturing is broader and contains various processes than 3D printing. For example, selective laser melting and electron-beam manufacturing are forms of additive manufacturing that do not create material layers. However, they still produce objects through adding material.

In most cases, additive manufacturing associates with commercial and industrial applications, while 3D printing popularly involves recreational and consumer applications.

Additive manufacturing applications

- The most common applications are ducting, rocket engine components, environmental control systems, composite tools, fuel tanks, and aircraft components.

- Medical. The applications include dental devices, orthopedic implant devices, custom saws, specialized instruments, and drill guides.

- Applications include resilient prototypes, grilles, paneling, elastomeric models, custom features, and complex ductwork.

- Its applications are stators, turbine nozzles, rotors, models, flow meter parts, pump manifolds, and pressure gauge pieces.

- Consumer products. They include entertainment costumes, lightweight models, and architectural models.

Why do you need to use additive manufacturing?

- The entry cost is becoming affordable. Because of technological advancements, the entry cost for additive manufacturing continues to decline. 3D printers and materials are becoming affordable even to small manufacturers.

- It saves energy and material. 3D printing involves creating objects through adding material. Therefore, the process minimizes the overall wastes. Also, consolidating the parts saves material cost and energy.

- There is an increase in demand. Additive manufacturing is relevant in the current market because of the increment in demand for its parts. It continues to shape and transform the future of manufacturing.

- You can easily change product versions. Additive manufacturing brings innovation and design to the forefront. It enables engineers to create various versions of a particular design cost-effectively.

- Training programs for all levels are readily available. The training includes fundamental training, technical training, and advanced training.

Key takeaway

Both additive manufacturing and 3D printing involve creating objects through adding material layers. Additive manufacturing is a broader term that includes 3D printing and other forms. The CAD software provides instructions to the 3D printer about the number of materials to add and where. Additive manufacturing products are cost-effective and save energy.

Choosing the right 3d printer for your specific business needs is important. Click here to learn more about how to choose a suitable industry-grade 3d printer and our top choices.